Is Precision Irrigation the Key to Feeding Billions?

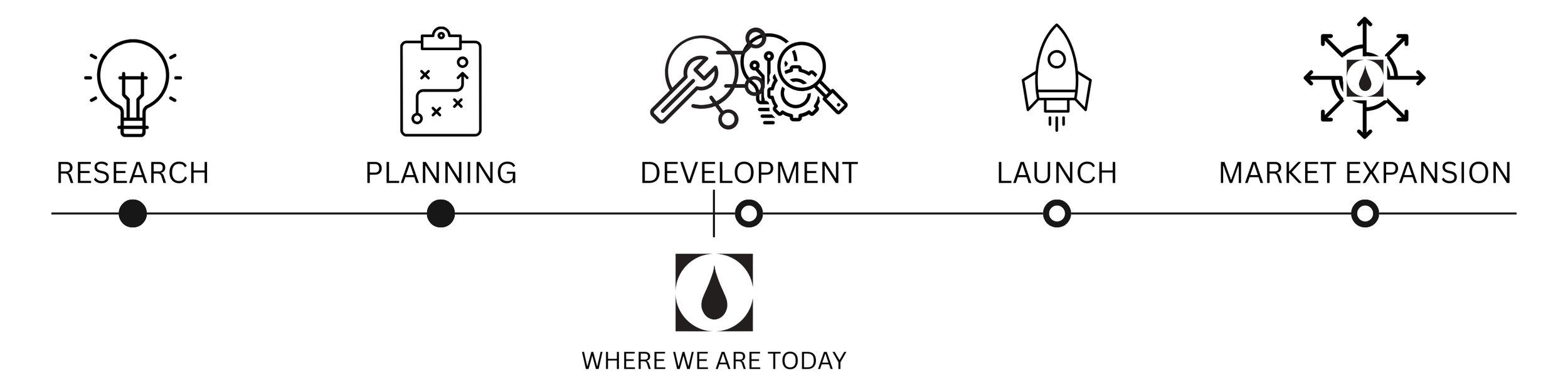

Concept-to-Market Roadmap

What’s Next?

Development Plan

-

Software: Has been designed to anticipate movement (using spline math, recalculating every 0.5° of rotation), and is ready for initial testing. Must correctly interpret linchpin signals, control tower movement, and ensure proper path following.

Linchpin: Positioned at the top of each tower, the pin must be designed to sense strain (forward/backward bending) and send signals to the control box for translation by the software.

Structural integrity: Superstructure must adequately support the weight of all critical components and irrigation capacities.

-

Build a prototype with four towers and expandable arms.

Towers communicate via linchpins and GPS paths.

System must demonstrate alignment, expansion, and torsion management.

GPS provides positional data while software coordinates tower movements.

-

Install at an agricultural test site.

Validate performance under real-world conditions (terrain dips, divots, etc.).

Gather feedback before scaling manufacturing.

Launch

Manufacturing & Market Plan

Year 1

Confirm Partnerships to Launch.

Critical Component Testing.

Build Initial Prototype.

Today

Year 2

Field Testing.

Initiate Manufacturing.

Year 3

First 20 Units to Market.

Year 4+

Scale Manufacturing Significantly.

Manufacturing Projections by 2035:

5,000+ Units Annually

Partner with us to Build the Future of Precision Irrigation.

The engineering is complete, the math is proven, and the demand is palpable. With the right investment and manufacturing strength, we can turn blueprints into prototypes, validate functionality, and capture early market share, together.